The robot must be equipped with multiple motors to be able to move the main body of the robot or the arms and limbs of the robot, which use the brushless direct current motor (BLDC) as the mainstream, in order to efficiently drive the brushless motor, it is necessary to choose the appropriate brushless motor driver. This article will introduce you to the characteristics and selection points of brushless motors and drives, as well as the product features of brushless motor drives from onsemi.

Brushless motors that are more efficient than brushless motors

Brushless motors and brushless motors are two different types of motors, and the main difference between them is whether the brush structure inside them is present. A pair of brushes inside the brushed motor are in contact with the rotating rotor, through which electrical energy is transferred to the rotor, resulting in rotation. The brushless motor does not require a brush and controls the direction of the current through an internal electronic controller (such as a transistor), applying an electromagnetic force directly to the magnet in the rotor, resulting in rotation.

Because brushless motors do not have brushes, they can reduce friction and wear at high speeds and are generally more efficient than brushed motors. In addition, brushless motors allow for more precise control of speed and torque, making them more suitable for applications requiring high-precision motion control.

In addition, because the brush part of the brushed motor is easy to wear and needs to be replaced regularly, more maintenance work is required. Brushless motors do not require such maintenance work and are therefore more convenient to use. However, under normal circumstances, the cost of brushless motors is higher than that of brushless motors, but with the continuous progress of brushless motor technology and the increase of market competition, the cost of brushless motors has been getting closer and closer to brushless motors.

Because brushless motors use electronic controllers to manage magnetic fields and currents, they are more efficient than traditional brushless motors, and brushless motors are able to provide high torque at low speeds, making them suitable for applications that require starting power, such as power tools and robots. Because brushless motors are able to operate at high rotational speeds, this makes them suitable for applications that require high-speed motion, such as drones and electric vehicles.

In addition, because brushless motors use electronic controllers rather than mechanical parts such as brushes and collectors, they are more durable than traditional brushed motors, plus because the operation of brushless motors is achieved by regulating the current through an electronic controller, rather than by mechanical friction and contact, they are generally quieter than traditional brushed motors. Because brushless motors have better performance and life than traditional brushless motors, they are widely used in a variety of applications, including industrial automation, household appliances, power tools, drones, electric vehicles, and more.

Brushless motor purchase tips

When choosing a brushless motor, you first need to determine what type of brushless motor your application requires, such as whether you need a brushless motor with high torque, high speed, or both, in order to provide the best performance for your application. In addition, it is necessary to select the correct brushless motor voltage and power according to the power supply and application needs. In general, the higher the input voltage and power, the better the performance of the brushless motor, but the corresponding cost will also increase.

On the other hand, you need to determine the speed range required for your application and choose a brushless motor that can provide the required speed. The efficiency of brushless motors is important because efficient brushless motors can save energy and reduce the cost of use. Therefore, choosing an efficient brushless motor can bring better performance and economic benefits to your application. Then you also need to choose a brushless motor with good durability and life, which can reduce the number of maintenance and replacement parts, and reduce the cost of use. Finally, you need to choose a reliable brand and high quality brushless motor to ensure that your application can run stably for a long time and bring you the maximum benefit.

Choose brushless motor drivers with emphasis

After selecting the brushless motor, you must begin to select the brushless motor driver. First, you need to determine the type of brushless motor you are using, such as DC brushless motor, stepper brushless motor, etc., and select the corresponding brushless motor driver. Then you need to choose the corresponding brushless motor driver according to the current and voltage of the brushless motor you are using. In general, the maximum current and maximum voltage of the brushless motor driver should be greater than the rated current and rated voltage of the brushless motor.

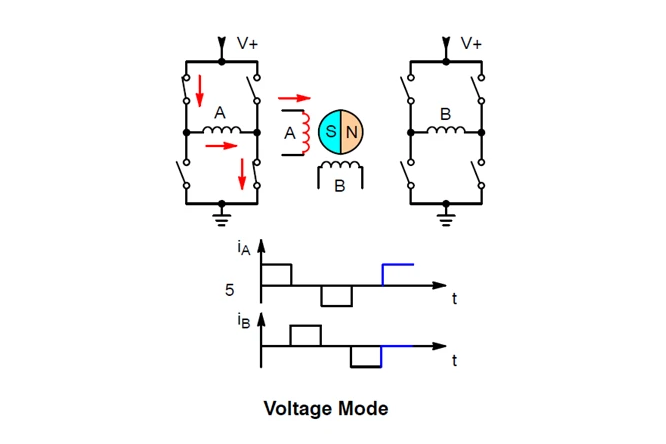

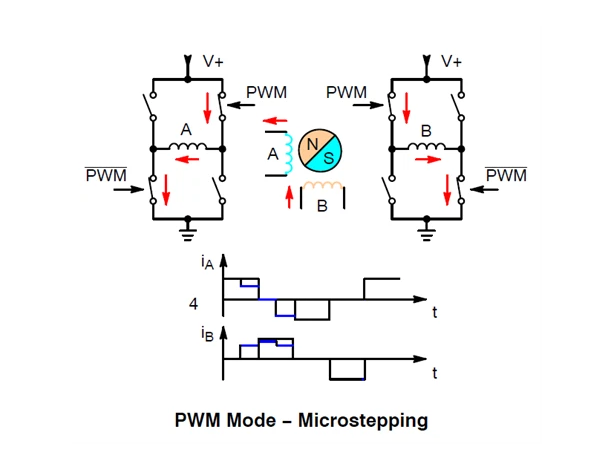

In addition, the brushless motor driver has a variety of control methods, such as PWM control, pulse direction control, etc., so you need to choose the control method suitable for your application, and then you need to determine whether your application needs speed control function, if so, you need to choose a brushless motor driver that supports speed control. Brushless motor drivers usually have overcurrent protection, overheat protection and other protection features, you need to determine whether the application needs these protection features to select the appropriate brushless motor driver. Of course, a reliable brand and high-quality brushless motor drivers will help your application run stably and ensure the overall system's operational efficiency.

Easy to use brushless motor driver

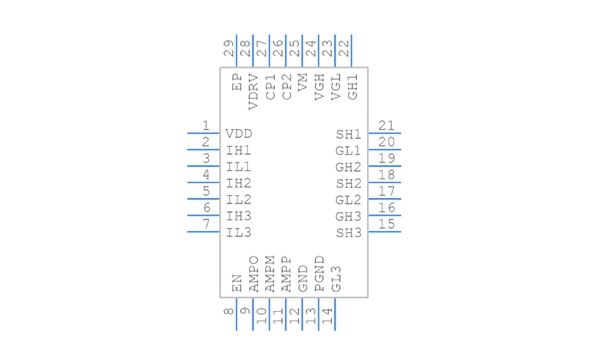

For high-precision robotic applications, On introduces the NCD83591 brushless motor driver, a three-phase 60V gate driver for motor control applications. The NCD83591 is fairly easy to use and features a high-gain-bandwidth current detection amplifier that is ideal for ladder motor control applications. It includes a configurable FET-constant gate drive source current from 5 to 250mA on the high side, which is twice the proportional feed current on the low side. High side gate and source output pin drives can be enabled with an embedded charge pump, allowing DC static drive and withstanding -12V DC voltage.

The NCD83591 supports internally generated gate drive supply voltages, and the wide operating voltage range makes the device ideal for industrial and commercial applications from 5 V (minimum) to 60 V (maximum), with tolerances from 4 V to 70 V. The gate driver comes in a small QFN28 (4x4) package with high integration, ideal for optimizing overall BOM costs.

The NCD83591 is a 60V three-phase gate driver with 70V absMax, has an embedded current detection amplifier, externally configurable as an embedded 10MHz GBW universal amplifier for high-end gate driven integrated charge pump, can be set in 16 Settings via the input level of the VDRV pin, Gate induction for cross conduction protection and optimized dead time.

NCD83591 can be used for current detection, embedded charge pump function allows DC static drive, supports strong blocking current to prevent self-conduction function, during VDD (core) power loss, internal gate pull down to GND, supports undervoltage lock on VM, VGL and VGH-VM, has 5 V/ 3.3V compatible 6 input control function, And up to 30 kHz motor PWM with independent six-gate control mode, 4 kV HBM and 1 kV CDM ESD protection, and is a lead-free device. On also introduced the NCD83591AS-GEVB evaluation board that supports NCD83591 to accelerate product development.

NCD83591 can be used in power equipment, construction and industrial automation, mobile applications, robots, etc. Common end products include power tools, outdoor power equipment, factory automation, building management, electric bicycles, electric scooters, hoverboards, collaborative robots, automatic guided vehicles, autonomous mobile robots and drones.

Peroration

The operation characteristics of the brushless motor are quite suitable for robot applications and can efficiently drive various actions of the robot, so it is more important to choose the right brushless motor and driver. On's brushless motor drivers for robotics are highly integrated, efficient, stable and low-cost, making them ideal for robotics applications.

Heisener Electronic is a famous international One Stop Purchasing Service Provider of Electronic Components. Based on the concept of Customer-orientation and Innovation, a good process control system, professional management team, advanced inventory management technology, we can provide one-stop electronic component supporting services that Heisener is the preferred partner for all the enterprises and research institutions.